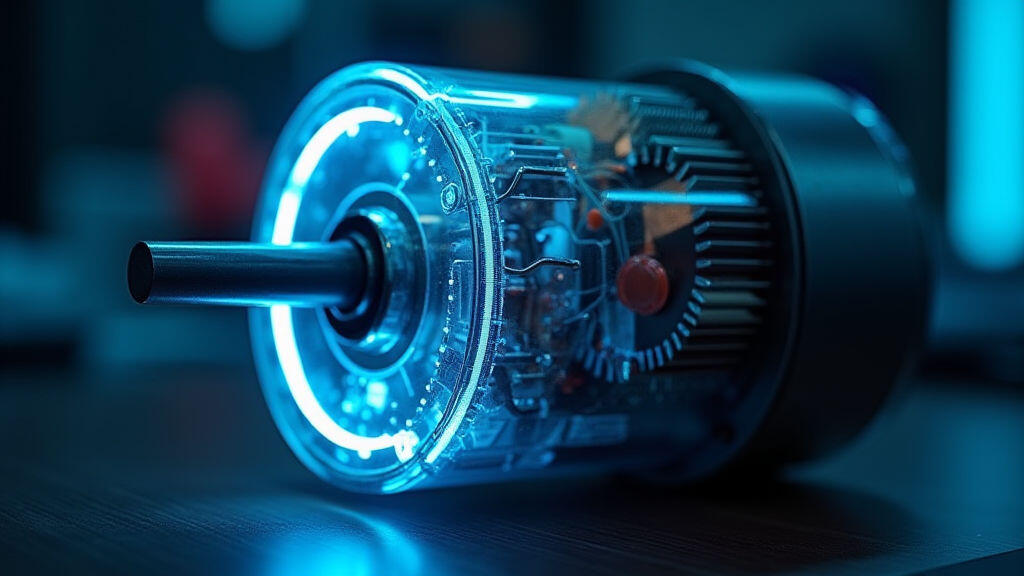

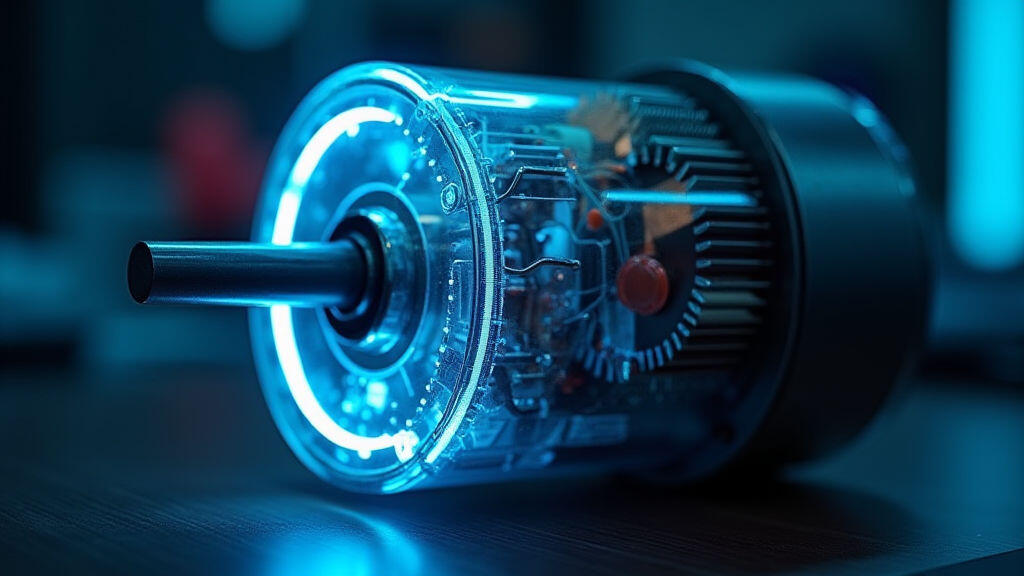

The manufacturing landscape is undergoing a rapid transformation, driven by the relentless pursuit of efficiency, precision, and flexibility. At the heart of this revolution lies automation, and micro DC gear motors are emerging as critical enablers across a broad spectrum of automated production lines. These miniature powerhouses, boasting advancements in design, performance, and control, are poised to reshape how industries approach complex tasks, contributing significantly to the ongoing Industry 4.0 evolution. This article explores the innovative application trends of new-generation micro DC gear motors, highlighting their key benefits and illustrating their impact on modern manufacturing.

The Rise of Micro DC Gear Motors: A Technological Leap

Traditional mechanical systems often struggle with size constraints, complex linkages, and limited precision. New-generation micro DC gear motors address these challenges with compact designs, high torque-to-size ratios, and enhanced efficiency. Advancements in materials science, miniaturization techniques, and power electronics have paved the way for motors that are smaller, lighter, and more powerful than ever before. These motors often incorporate features like integrated encoders for precise position feedback, leading to improved accuracy and control. The shift towards IoT and IIoT (Industrial Internet of Things) further fuels the demand, as these motors can be easily integrated into smart manufacturing ecosystems for remote monitoring and predictive maintenance.

Key Trends Driving Adoption:

Several key trends are fueling the escalating demand for these micro DC gear motors in automated production lines:

Applications Across Industries:

The versatility of micro DC gear motors translates into a wide range of applications across diverse industries:

The Impact of Industry 4.0 and the Metaverse:

The convergence of Industry 4.0 technologies, such as AI, machine learning, and cloud computing, is further amplifying the potential of micro DC gear motors. Predictive maintenance algorithms can leverage data from motor encoders to anticipate failures and schedule maintenance proactively. AI-powered control systems can optimize motor performance in real-time, improving efficiency and reducing energy consumption. The nascent Metaverse concept also presents opportunities. Simulations within a Metaverse environment can be used to optimize robotic arm designs and assembly line layouts, ensuring optimal motor selection and placement.

MES-Drive: A Leader in Micro DC Gear Motor Technology

MES-Drive is at the forefront of innovation in micro DC gear motor technology. The company offers a comprehensive portfolio of high-performance motors, customized solutions, and comprehensive technical support. MES-Drive consistently invests in research and development, pushing the boundaries of miniaturization, efficiency, and connectivity. Their commitment to quality and customer satisfaction has established them as a trusted partner for manufacturers worldwide.

Conclusion: Powering the Future of Manufacturing

New-generation micro DC gear motors are no longer just niche components; they are essential building blocks for the future of automated production. Their compact size, high precision, energy efficiency, and connectivity capabilities are perfectly aligned with the demands of Industry 4.0 and the ongoing digital transformation of manufacturing. As industries increasingly embrace automation, the demand for these miniature powerhouses will continue to grow. The integration of advanced control algorithms, IIoT connectivity, and AI-driven optimization will further enhance their performance and unlock new possibilities. MES-Drive, with its unwavering commitment to innovation, is well-positioned to lead the way in this exciting evolution, helping manufacturers achieve unprecedented levels of efficiency, flexibility, and precision. The ongoing advancements in this field, intertwined with the emergence of technologies like the Metaverse, signal a future where automated production lines are even more intelligent, responsive, and adaptable – all powered by the unassuming yet remarkably powerful micro DC gear motor.

Leave A Reply

Your email address will not be published. Required fiels are marked